|

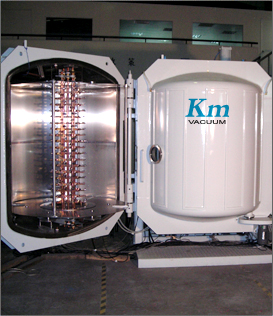

KUEN MIN Founded in 1991, over the years is responsible for maintaining its intentions, sincere practical entrepreneurship, is committed to providing high-quality products and services efforts. Accumulated ten years of practical experience to provide you with perfect vacuum equipment manufacturing planning and recommendations. Our goal is tailored for your high-quality vacuum equipment for your different product needs, from the graphical layout and planning and production, to finished the whole plant output, real-time after-sales service, is your best partner to create a cause.

Provided by the Company's products and services include: high-vacuum deposition machine, high vacuum sputtering machines, continuous vacuum coating chamber, the liquid crystal into the machine, multi-arc ion vacuum coating machine, various types of vacuum equipment manufacturers to develop and maintain , vacuum pump, vacuum system components and so on. If you have special needs other products are welcome to contact the caller. In addition, the company is also committed to promoting industry-university cooperation, the application of vacuum equipment to engage in related research scholars from time to time to master the latest developments.

1991 |

The establishment of the factory located in Linkou. |

1993 |

Manufacture of plastic vacuum deposition equipment. |

1995 |

Manufacture of continuous vacuum sputtering cavity in AVCT. |

1996 |

Manufacturing EMI (anti-cell-wave interference) Continuous sputtering empty cavity in the PT. |

1997 |

Developed small-size LCD panel into the machine, moved to Taoyuan Nankan expansion plans. |

1998 |

Prior to the completion of open-TFT-LCD panel liquid crystal into the machine, to AUO. |

1999 |

Manufacture of experimental multi-layer vacuum coating systems to the Central University by photoelectric. |

2000 |

Developed multi-arc ion vacuum coating machine, production and sales. |

2001 |

Adapt to business growth needs, the purchase of plant Ping 327. |

2002 |

Continuous manufacture of vacuum coating chamber (for mobile phones such as the appearance of buttons chassis metal mold layer). |

2002 |

Huwei Institute of Technology and the Industry-University Collaboration "with integrated circuit lead-frame type of precision stamping die coating diamond-like carbon films on the characteristics and applied research", by the National Science Council grant. |

2003 |

Completed the development of PCB drilling and milling tool coating equipment. |

2004 |

Completed the development of vertical single-door NCVM professional Coater. |

2006 |

Passed ISO9001 certification. |

|

ISO

|

|

|

|